Silicon Oil

Price 280 INR/ Kilograms

Silicon Oil Specification

- Properties

- Excellent thermal stability, Low surface tension, Good electrical insulating properties, High water repellency, Non-reactive under normal conditions, Non-toxic

- Usage

- Industrial

- Ingredients

- Polydimethylsiloxane (PDMS)

- Product Type

- Silicon Oil

- Physical Form

- Liquid

- Refractive Rate

- 1.402 (at 25C)

- Ph Level

- Neutral (7)

- Grade

- Industrial Grade

- Molecular Formula

- (C2H6OSi)n

- Poisonous

- NO

- EINECS No

- 203-492-7

- Melting Point

- -50C to -60C

- Shape

- Liquid (no fixed shape)

- Molecular Weight

- Varies depending on viscosity, typically 162.38 g/mol (repeating unit)

- Shelf Life

- 24 months

- Appearance

- Clear, colorless liquid

- Purity

- >99%

- Taste

- Odorless and tasteless

- Application

- Lubrication, Hydraulic fluids, Insulating fluids, Water repellents, Cosmetics, Polishes, Pharmaceuticals, Paper coating

- Solubility

- Insoluble in water; soluble in organic solvents like benzene and toluene

- Storage

- Room Temperature

- Density

- 0.96 Gram per cubic centimeter(g/cm3)

- HS Code

- 39100090

- CAS No

- 63148-62-9

- Smell

- Odorless

- Structural Formula

- [SiO(CH3)2]n

Silicon Oil Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 5 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Silicon Oil

A silicone oil is any liquid polymerized siloxane with organic side chains. The most important member is polydimethylsiloxane. These polymers are of commercial interest because of their relatively high thermal stability and their lubricating properties ApplicationsExceptional Thermal and Electrical Properties

Silicon Oil exhibits outstanding thermal stability and boasts a dielectric strength above 15 kV/mm, ensuring reliable insulation in electrical and electronic applications. Its high flash point and ability to resist decomposition at elevated temperatures make it a premium choice in demanding industrial environments for both electrical and thermal management.

Wide-Ranging Industrial Applications

Owing to its non-toxicity and broad compatibility, Silicon Oil is widely used in industries ranging from hydraulics to cosmetics. Its insolubility in water, ability to act as a water repellent, and stable lubricating properties make it a preferred option in the manufacturing of polishes, pharmaceuticals, paper coatings, and more.

Safe, Compliant, and User-Friendly

Manufactured to industrial-grade standards and compliant with REACH and RoHS, Silicon Oil is non-toxic, odorless, and neutral in pH, making it safe for handlers and various applications. Its long shelf life, stable physical properties, and bulk availability ensure convenience and reliability for industrial users throughout India.

FAQs of Silicon Oil:

Q: How is Silicon Oil used in industrial applications?

A: Silicon Oil is used as a lubricant, hydraulic fluid, electrical insulating fluid, water repellent, and more. Industries utilizing this product include automotive, cosmetics, pharmaceuticals, and manufacturing, benefiting from its stability, compatibility, and non-toxic nature.Q: What are the main benefits of choosing Silicon Oil over other industrial fluids?

A: The primary benefits include excellent thermal stability, superior dielectric strength, low surface tension, and high compatibility with plastics, rubbers, and metals. These properties enable its use in demanding applications while ensuring safety and non-reactivity.Q: When should Silicon Oil be applied, and how frequently does it need replacement?

A: Silicon Oil is typically applied when high-performance thermal, electrical, or lubricating properties are required. Its long shelf life (24 months) and non-reactive nature mean replacements are infrequent unless contaminated or depleted during process usage.Q: Where can Silicon Oil be stored and what are the ideal storage conditions?

A: Silicon Oil should be stored in a cool, dry place at room temperature. It is packaged in drums, cans, or in bulk, and should be kept sealed when not in use to prevent contamination and degradation.Q: What is the process of handling and disposing of Silicon Oil?

A: Handling Silicon Oil is straightforward due to its non-toxic, non-hazardous nature and odorless, clear liquid form. Disposal should adhere to local regulations, though its non-reactivity and compliance with REACH and RoHS guidelines make it safe for standard industrial waste procedures.Q: How does Silicon Oils physical form and properties contribute to its industrial performance?

A: Its clear, colorless, and odorless liquid form, combined with low viscosity (1001000 cSt), high thermal conductivity, and remarkable water repellency, allows for smooth application and reliable performance, especially in lubrication and insulation roles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Chemicals Category

Lactic Acid

Price 245.0 INR / Liter

Minimum Order Quantity : 25 Liters

Grade : Food Grade

Product Type : Organic Acid

Physical Form : Liquid

Application : Other , Food, beverage, cosmetic, pharmaceutical, chemical, and industrial applications

menthol crystals

Price 1841 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Grade : Pharmaceutical/Food grade

Product Type : Organic Compound

Physical Form : Other, Crystalline solid

Application : Other , Pharmaceuticals, food flavoring, cosmetics, oral care, aromatherapy

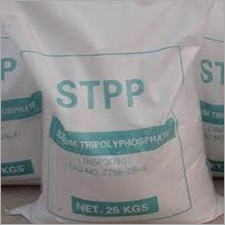

Sodium Tripolyphosphate

Price 60 INR / Kilograms

Minimum Order Quantity : 25 Kilograms

Grade : Technical Grade

Product Type : Sodium Tripolyphosphate

Physical Form : Powder

Application : Industrial

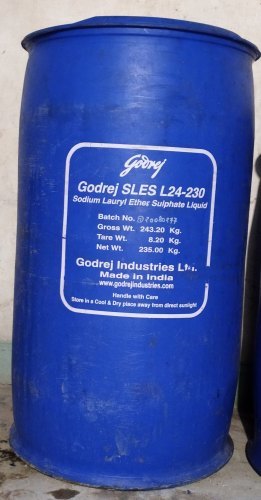

Sles Liquid

Price 62 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Grade : Industrial Grade

Product Type : Sles Liquid

Physical Form : Liquid

Application : Industrial

GST : 24AAIPZ4706C1ZR

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS